Abstract

Multi-functional films with tunable electrical and optical properties are key to developing efficient and visually attractive silicon solar panels. Yet, a single-component material has not been able to address the challenge. Researchers now have found a means to blend multiple polymers and inorganic components in nanocomposite films. The optical and electrical properties of the nanocomposite films can be easily tailored to meet the requirement of rendering silicon solar cells of any designer color whilst maintaining efficient power conversion efficiencies. Cells with vivid colors offer the promise of the otherwise dull silicon solar panels as decorative structural materials.

Keywords

Silicon, Solar Cells, Dielectric films, Colorful, Polymers, Nanocomposites.

Introduction

Solar cells made of crystalline silicon (c-Si) have dominated the world’s solar energy market to date [1,2]. Meanwhile, there is growing interest in adding new features or properties to c-Si solar cells such as vibrant colors that make them particularly attractive for decorative applications [3,4]. Nevertheless, c-Si solar cells with regular p-n junctions present a sizable challenge in generating colors across the visible spectrum due to their fixed device structure and limited materials selection. Hence, typical c-Si solar cells are visually dull and are not suitable for integration with buildings [5], passenger vehicles [6], and so on.

To tackle this issue, several methods such as micro-nano manufacturing techniques, photonic crystal patterning, and thin dielectric films, have been used to achieve colored c-Si solar cells [7-9]. These methods, however, require complicated fabrication equipment and are expensive to industrialize. Planar heterojunction c-Si solar cells, consisting of c-Si and novel materials (such as graphene [10], carbon nanotubes [11], and conducting organic semiconductors [12]), provide a very simple way to construct colorful solar panels by a thin-film coating that serves as a light reflection layer and a charge collection contact [13,14]. In particular, researchers have recently made significant progress in making conductive polymer nanocomposites on c-Si solar cells to achieve full colors [15]. In this commentary, we discuss this recent development on brightening up silicon cells by polymer nanocomposite coatings.

Methods to Colorize c-Si Solar Cells

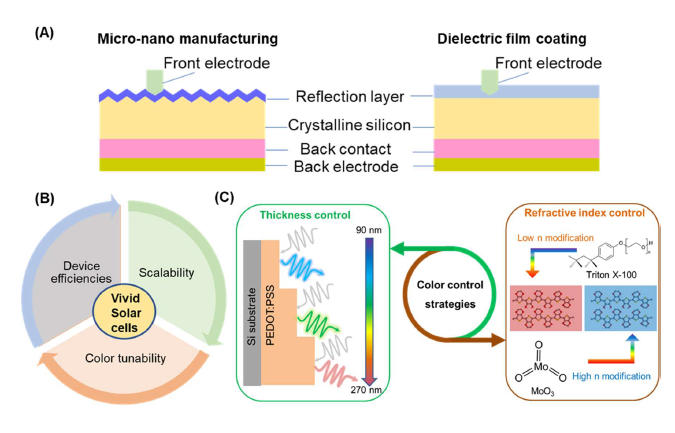

Colored c-Si solar cells are attractive in practical applications such as rooftops, windows, electrical vehicles, etc. Bandgap-tunable photovoltaic materials such as organic dyes and metal halide perovskites in the visible range have been reported to realize colorful solar cells [16-19], but the deployment of solar cells based on these emerging materials lags behind c-Si solar cells so far. Strategies to the development of colorful c-Si solar cells with a planar structure are, in general, by varying either the light transmission or the light reflection. As c-Si is intrinsically opaque, a commonly reported method to make colorful c-Si solar cells is to add optical reflective layers on the top of an opaque c-Si wafer [20]. Among the reflective coating strategies, previous studies have shown that introducing particular micro-/nano-structured coating layers on c-Si wafers can scatter the incident light and hence generate structural color to c-Si solar cells (Figure 1A, left) [3,4,20], and even neutral-colored c-Si solar cells have been enabled by introducing micron-holes on an opaque c-Si wafer [7]. Though microfabrication methods and tools to make micro-/nano-structured coating layers are broadly used in the microelectronics industry, complex manufacturing processes make them prohibitively expensive for the potential solar market.

Figure 1. (A) Illustration of colorful c-Si solar cells enabled by using either micro-nano structures (left) or (right) surface coatings. (B) Key factors in fabricating-colored solar cells: device efficiencies, scalability, and color tunability. (C) Schematic chart showing colored planar heterojunctions c-Si solar cells based on PEDOT:PSS based nanocomposite coatings. Figure is reproduced with permission [15].

Coating dielectric films directly on an opaque c-Si wafer offer a more attractive alternative to generate colors by varying the film thickness (i.e., optical paths) (Figure 1A, right). In this case, the dielectric coatings can be manufactured by using simple film deposition methods [14,17], making cost-effective colorful solar cells possible. Meanwhile, the refractive index and conductivity of the dielectric films can be precisely controlled [21,22], and thus concurrent improvements in device performance and color tunability can be obtained (Figure 1B). What’s more, those materials can be selected from a wealth of polymer materials and inorganic materials, making them useful in practical applications of colorful c-Si solar cells. The challenge is to combine these various materials in a composite form to obtain multi-functional films meeting the targeted tunable electrical and optical properties.

Polymer Nanocomposites for Colorful c-Si Solar Cells

Poly(3,4-ethylenedioxythiophene) polystyrene sulfonate, also known as PEDOT:PSS, is a transparent conductive polymer consisting of a mixture of the ionomers poly(3,4- ethylenedioxythiophene) and polystyrene sulfonate (PSS). Owing to its unique combination of ductility, transparency, conductivity, and facile fabrication, PEDOT:PSS has become a popular material serving as charge-selective contacts at the front electrode of c-Si solar cells to form a planar heterojunction [14,21]. Most recently, Yu et al. reported that the thickness and the refractive index can be tailored to produce colors on c-Si solar cells [15]. Typically, changes to the thickness of PEDOT:PSS nanocomposites modulate optical phase variations of light propagating in films, resulting in either destructive or constructive interference. The optical destructiveness or constructiveness leads to various color appearances on c-Si wafers (Figure 1C). In addition, changes in refractive index of PEDOT:PSS nanocomposites can vary the light reflection across the visible light spectrum. For instance, the porous PEDOT:PSS/Triton X-100 nanocomposite is one effective means to tune the optical refractive index by controlling the film porosity. Blending high refractiveindex MoO3 into the PEDOT:PSS films are shown to be another effective means to tune the refractive index (Figure 1C). As a consequence, various optical interference patterns (i.e., colors) on c-Si solar cells can be engineered simply by regulating the thickness and refractive index of PEDOT:PSS-based nanocomposites.

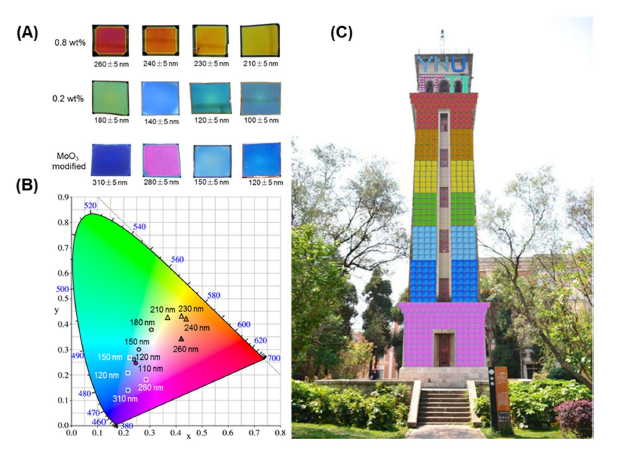

The reported results show that various PEDOT:PSS nanocomposite films on planar c-Si solar cells do produce various colors (Figure 2A). The CIE color coordinates showed that in comparison to 0.2 wt% Triton X-100 doping film, the color of 0.8 wt.% Triton X-100 doping films moves towards the red area with high color purity (Figure 2b). For the PEDOT:PSS-MoO3 nanocomposites, the colorselected range can expand to the blue-violet region with higher color saturation. Thus, a combination of thickness control and optical refractive index adjustment enables the fabrication of planar c-Si/PEDOT:PSS solar cells with vivid colors over a wide color gamut. These colorful c-Si cells could potentially be used as decorative solar panels on buildings as shown in Figure 2C (an old Bell Tower).

Figure 2. (A) Photographic pictures c-Si solar cells with PEDOT:PSS-based organic nanocomposites, wherein low refractive index materials (Triton X-100) and high refractive index materials (MoO3 ) are blended into PEDOT:PSS host matrix, respectively. (B) Colors of the planar c-Si solar cells in the CIE 1931 chromaticity space. (C) Illustration of a Bell tower with colorful c-Si solar panels. A-C: Reproduced with permission [15].

High-performance Colorful c-Si Solar Cells

The high device efficiency and high color saturation are the prerequisites to practical applications of colorful c-Si solar cells. There is, however, a trade-off between the optical and electrical properties of the PEDOT:PSS polymer nanocomposites. As for the PEDOT:PSS polymers, previous reports have shown that their conductivities are determined by the PSS-to-PEDOT ratio and the PEDOT chains structure within the films [23,24]. Consequently, varying the PSS-to-PEDOT ratios within the thin films is the most common approach to maximize the conductivity of PEDOT:PSS dielectric films. There is a wealth of literature showing that the PEDOT:PSS polymer is sensitive to polar solvents [21,23], such as Dimethyl sulfoxide (DMSO), methanol, N,N-Dimethylformamide (DMF), etc. This indicates that the conductivity of the PEDOT:PSS layer can be improved by rewetting the surface of as-prepared films using solvent engineering. Regarding vivid c-Si solar cells with PEDOT:PSS nanocomposite films, Yu et al. discovered that, in analogous to the modifications of optical properties, PEDOT:PSS blended with the same low/high refractive materials can also enhance electrical properties. To this end, they systematically optimized processes to maximize device performance. And they found that there are negligible changes in both open-circuit voltages and fill factor for a variety of colored c-Si solar cells, whereas a short-circuit current density exhibits a noticeable increase once the color varies from pink to purple. The optimized PEDOT:PSS nanocomposites are found to maintain high device efficiencies ranged from 10.6% to 13.2%, which is among the top planar heterojunction c-Si solar cells [25-27].

Conducting Polymer Nanocomposites for Other Applications

As PEDOT:PSS nanocomposites can be made by various solution-phase techniques such as spin coating, spray coating, ink-inject printing, doctor blade coating, slot-die coating, etc., it may find other applications in a variety of devices. For example, PEDOT:PSS with matching energy levels and excellent transparency, has been used to enhance hole-carrier injection or extraction in emerging optoelectronic devices [28], and even in these cases, highly conducive PEDOT:PSS materials are regarded as a potential replacement of other commercial semitransparent electrodes [29]. PEDOT:PSS nanocomposites are expected to receive growing interest in wearable and smart selfpowered flexible solar cells. The operation of flexible solar cells is especially dependent on the mechanical ductility of the functional layers. The PEDOT:PSS nanocomposite also provides robust interfaces with other functional layers. In the future, the polymer nanocomposites could potentially be used to brighten up other solar cells such as perovskite solar cells, organic solar cells, and other thin-film solar cells.

In addition to solar cell applications, it has been demonstrated that a few to tens of nanometers thick organic films on metallic substrates can achieve functionalities such as anti-reflection, high-reflection and dichroism [30]. Various structural color images on metallic substrates have been demonstrated by modifying monochromic conducting polymer nanofilms via vapor phase polymerization and ultraviolet light patterning [31]. Thus, polymer nanocomposites are expected to be useful as optical coatings on metallic substrates.

Conclusion

In summary, polymer nanocomposite films provide a flexible materials platform to tune optical constants and optical paths. Through the selection of a suitable nanocomposite and a film thickness, vivid c-Si solar cells with various color shades have been achieved while maintaining a peak power conversion efficiency of 13.2%, which is comparable to regular planar heterojunction c-Si solar cells.

Conflicts of Interests

The authors declare no conflict of interest.

Acknowledgements

We would like to acknowledge the financial support from the Natural Science and Engineering Research Council of Canada.

References

2. Allen TG, Bullock J, Yang X, Javey A, De Wolf S. Passivating contacts for crystalline silicon solar cells. Nature Energy. 2019 Nov;4(11):914-28.

3. Zhang Y, Chen S, Hu D, Xu Y, Wang S, Qin F, Cao Y, et al. Coloring solar cells with simultaneously high efficiency by low-index dielectric nanoparticles. Nano Energy. 2019 Aug 1;62:682-90.

4. Soman A, Antony A. Colored solar cells with spectrally selective photonic crystal reflectors for application in building integrated photovoltaics. Solar Energy. 2019 Mar 15;181:1-8.

5. Røyset A, Kolås T, Jelle BP. Coloured building integrated photovoltaics: Influence on energy efficiency. Energy and Buildings. 2020 Feb 1;208:109623.

6. Li X, Li P, Wu Z, Luo D, Yu HY, Lu ZH. Review and perspective of materials for flexible solar cells. Materials Reports: Energy. 2020 Dec 14.

7. Lee K, Kim N, Kim K, Um HD, Jin W, Choi D, Park J, et al. Neutral-colored transparent crystalline silicon photovoltaics. Joule. 2020 Jan 15;4(1):235-46.

8. Qiu K, Bittkau K, Lambertz A, Duan W, Liang Z, Shen H, Rau U, Ding K. The Impact of Reflectance Variation in Silicon Heterojunction Solar Cells and Modules on the Perception of Color Differences. IEEE Journal of Photovoltaics. 2021 Jan 14;11(2):306-11.

9. Lim JW, Kim G, Shin M, Yun SJ. Colored a-Si: H transparent solar cells employing ultrathin transparent multi-layered electrodes. Solar Energy Materials and Solar Cells. 2017 Apr 1;163:164-9.

10. Li X, Zhu H, Wang K, Cao A, Wei J, Li C, Jia Y, et al. Graphene-on-silicon Schottky junction solar cells. Advanced Materials. 2010 Jul 6;22(25):2743-8.

11. Di J, Yong Z, Zheng X, Sun B, Li Q. Aligned carbon nanotubes for high-efficiency Schottky solar cells. Small. 2013 Apr 22;9(8):1367-72.

12. He J, Gao P, Ling Z, Ding L, Yang Z, Ye J, Cui Y. Highefficiency silicon/organic heterojunction solar cells with improved junction quality and interface passivation. ACS nano. 2016 Dec 27;10(12):11525-31.

13. Selj JH, Mongstad TT, Søndenå R, Marstein ES. Reduction of optical losses in colored solar cells with multilayer antireflection coatings. Solar Energy Materials and Solar Cells. 2011 Sep 1;95(9):2576-82.

14. Sun Z, He Y, Xiong B, Chen S, Li M, Zhou Y, Zheng Y, et al. Performance-Enhancing Approaches for PEDOT: PSSSi Hybrid Solar Cells. Angewandte Chemie International Edition. 2021 Mar 1;60(10):5036-55.

15. Yu LM, Man JX, Chen T, Luo D, Wang J, Yang H, Zhao YB, et al. Colorful conducting polymers for vivid solar panels. Nano Energy. 2021 Jul 1;85:105937.

16. Wang H, Li J, Dewi HA, Mathews N, Mhaisalkar S, Bruno A. Colorful Perovskite Solar Cells: Progress, Strategies, and Potentials. The Journal of Physical Chemistry Letters. 2021 Jan 27;12(4):1321-9.

17. Jiang Y, Luo B, Jiang F, Jiang F, Fuentes-Hernandez C, Liu T, Mao L, et al. Efficient colorful perovskite solar cells using a top polymer electrode simultaneously as spectrally selective antireflection coating. Nano Letters. 2016 Dec 14;16(12):7829-35.

18. Zhang W, Anaya M, Lozano G, Calvo ME, Johnston MB, Míguez H, Snaith HJ. Highly efficient perovskite solar cells with tunable structural color. Nano Letters. 2015 Mar 11;15(3):1698-702.

19. Li X, Xia R, Yan K, Ren J, Yip HL, Li CZ, Chen H. Semitransparent organic solar cells with vivid colors. ACS Energy Letters. 2020 Sep 2;5(10):3115-23.

20. Ji C, Zhang Z, Masuda T, Kudo Y, Guo LJ. Vivid-colored silicon solar panels with high efficiency and non-iridescent appearance. Nanoscale Horizons. 2019;4(4):874-80.

21. Yu LM, Chen T, Feng N, Wang R, Sun T, Zhou Y, Wang H, et al. Highly Conductive and Wettable PEDOT: PSS for Simple and Efficient Organic/c-Si Planar Heterojunction Solar Cells. Solar RRL. 2020 Apr;4(4):1900513.

22. Yang L, Chen J, Ge K, Guo J, Duan Q, Li F, Xu Y, Mai Y. Polymer/Si heterojunction hybrid solar cells with rubrene: DMSO organic semiconductor film as an electron-selective contact. The Journal of Physical Chemistry C. 2018 Sep 26;122(41):23371-6.

23. Chen K, Hu Q, Liu T, Zhao L, Luo D, Wu J, Zhang Y, et al. Charge-carrier balance for highly efficient inverted planar heterojunction perovskite solar cells. Advanced Materials. 2016 Dec;28(48):10718-24.

24. Vosgueritchian M, Lipomi DJ, Bao Z. Highly conductive and transparent PEDOT: PSS films with a fluorosurfactant for stretchable and flexible transparent electrodes. Advanced Functional Materials. 2012 Jan 25;22(2):421-8.

25. He J, Gao P, Liao M, Yang X, Ying Z, Zhou S, Ye J, Cui Y. Realization of 13.6% efficiency on 20 µm thick Si/ organic hybrid heterojunction solar cells via advanced nanotexturing and surface recombination suppression. Acs Nano. 2015 Jun 23;9(6):6522-31.

26. Zhu J, Yang X, Yang Z, Wang D, Gao P, Ye J. Achieving a Record Fill Factor for Silicon–Organic Hybrid Heterojunction Solar Cells by Using a Full-Area Metal Polymer Nanocomposite Top Electrode. Advanced Functional Materials. 2018 Mar;28(13):1705425.

27. Chen L, Gao Z, Zheng Y, Cui M, Yan H, Wei D, Dou S, et al. 14.1% efficiency hybrid planar-Si/organic heterojunction solar cells with SnO2 insertion layer. Solar Energy. 2018 Nov 1;174:549-55.

28. Luo D, Li X, Dumont A, Yu H, Lu ZH. Recent Progress on Perovskite Surfaces and Interfaces in Optoelectronic Devices. Advanced Materials. 2021 Jun 17:2006004.

29. Kim YH, Sachse C, Machala ML, May C, Müller- Meskamp L, Leo K. Highly conductive PEDOT: PSS electrode with optimized solvent and thermal posttreatment for ITO-free organic solar cells. Advanced Functional Materials. 2011 Mar 22;21(6):1076-81.

30. Kats MA, Blanchard R, Genevet P, Capasso F. Nanometre optical coatings based on strong interference effects in highly absorbing media. Nature Materials. 2013 Jan;12(1):20-4.

31. Chen S, Rossi S, Shanker R, Cincotti G, Gamage S, Kühne P, Stanishev V, et al. Tunable Structural Color Images by UV-Patterned Conducting Polymer Nanofilms on Metal Surfaces. Advanced Materials. 2021 Aug;33(33):2102451.