Abstract

Nanotechnology is an evolved field for the transition of traditional agriculture and the food business into a new form to facilitate food industry growth. Nanobased technology finds wide-ranging applications in development of nanosensors, nanopackages, nanoneutraceuticals and functional foods as well as safe delivery of micronutrients and bioactive components. To present a review on this, we have recently published an article that has addressed some recent trends and advancements of nanotechnology, its applications in food processing sector, concerned health regulatory challenges and risk assessment issues. The ideas of briefing the contents, updating with latest nanoscience and technological breakthroughs and making a summarized extended version of our earlier review were developed for a simple and better understanding of the reader. So, the basic aim of this communication is to provide a quick overview of the entire domain of nanotechnology covering all its aspects in a concise form. Despite being nanotechnology a promising technique with safety features, significant studies in the nano food system and general consumer awareness are still necessary that are also highlighted in this article.

Keywords

Nanomaterials; Synthesis; Applications; Safety hazards

Introduction

Nanotechnology is an evolving revolution with enormous promise in a variety of fields, including mechanics, medicine, and the food business. Nanoparticles owing to having greater surface area and enhanced rates of mass transfer seem to pose higher biological and chemical activities, penetrability, catalytic behaviour, enzymatic reactivity, and quantum properties compared to large particles with the identical composition [1]. Nanomaterials are categorised based on their size, nature, structures and characteristics. Nanoparticles with high surface volume ratio can show excellent physicochemical properties in terms of diffusivity, solubility, bioavailability, intoxicity, optics, thermodynamics and magnetism [2]. Nanoscale food additives in forms of flavouring agent, preservatives, antimicrobial sensors, packaging materials, encapsulated food components, etc. are known to influence the nutrient composition as well as improve product shelf life, flavour and texture [3]. It can even be employed as food quality and safety indicators by detecting food pathogens [4]. In food processing, nano-encapsulation of food ingredients, additives (like color and flavour) and nutritional supplements (like, proteins, vitamins, bioactives and antioxidants) produce nanocapsules that can be introduced in functional foods. Apart from acting as protective barriers, this also offers bad taste and off-flavor masking, controlled release of nutrients by smart/intelligent systems, and better dispensability of waterinsoluble ingredients via nanotherapy. Electrospun nanofibres are gaining extensive attention as encapsulating materials or food packaging films [5].

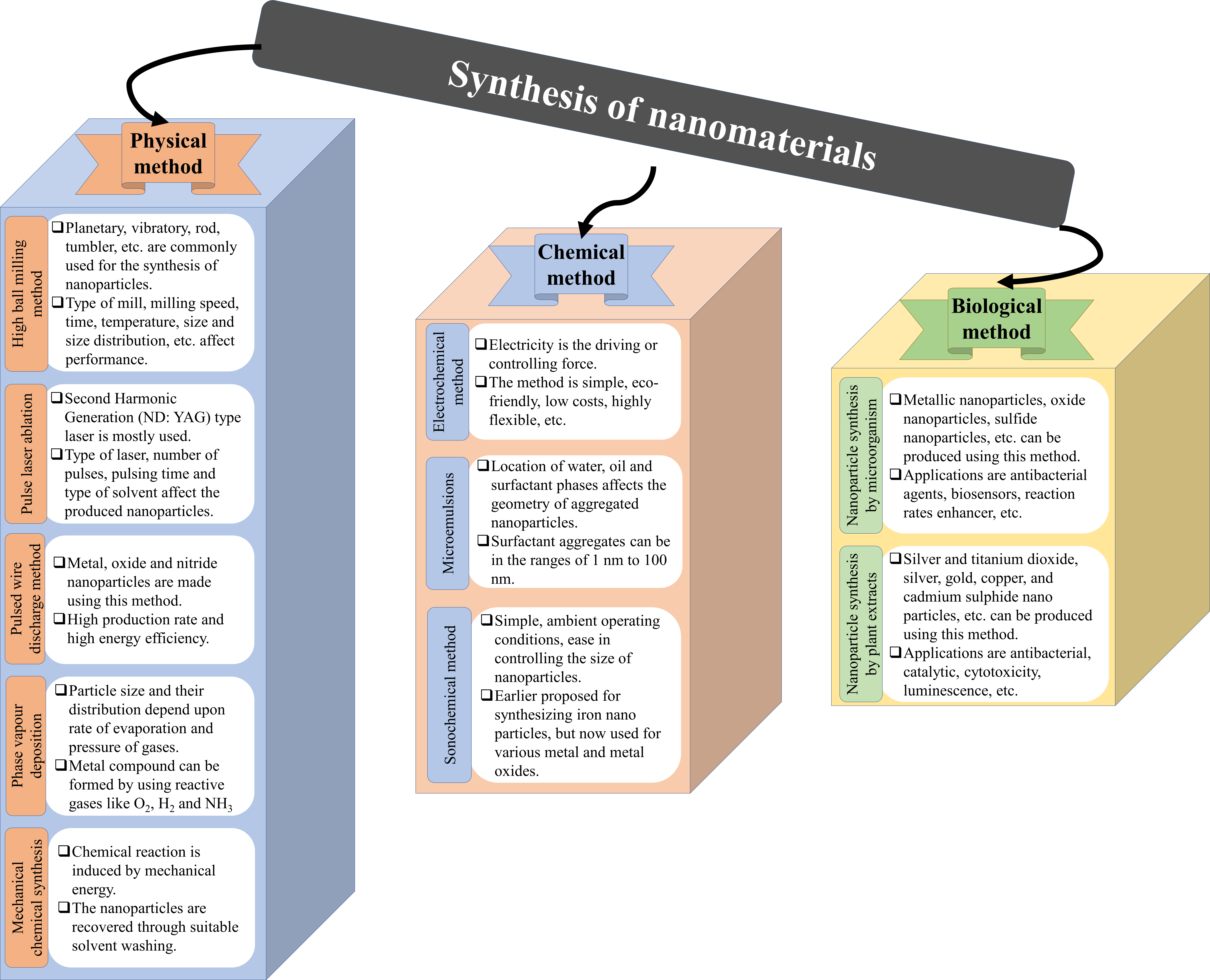

Nanostructured materials mostly consist of quantum dots (QDs), nanorods, nanoparticles, nanowires, nanoplate, etc. and mainly form layered films, atomic and wire structures. Nanostructures are produced using food grade ingredients simply via layer-by-layer techniques (an economical approach). There are three techniques available for synthesizing different types of nanomaterials which are majorly based on the materials of interest [6]. One is physical method where the mechanical forces and evaporation are generally utilized for the nanomaterial synthesis which includes milling, ultrasound emulsification, homogenization and microfluidization [7]. The chemical methods have certain advantages over the physical ones, like, simplicity in operation, low temperature (<300°C) synthesis, easy conversion of the liquid product to thin films or dry powder, varied options for a variety of shapes and sizes of nanoparticles, incorporation of useful minerals during synthesis is possible, etc. [8]. The third is biological way that holds unique attention among researchers due to its advantages, like, safe, no use of toxic chemicals, eco-friendly, inexpensive, reproducibility in production, easy scaling-up, well defined morphology, etc. Nanoparticle production by plant extracts and microorganisms like bacteria, fungi, yeasts, etc., are some biosynthesis means [9,10]. Nanoparticles prepared by plant extract mediated synthesis method are being studied for their antioxidant activities, antibacterial properties, in-vitro cytotoxicity applications on human cancer cell lines (i.e. anticancer activity), in photodynamic therapy and in treatment of tumor hyperthermia [11,12]. The details of these techniques are presented in Figure 1.

Figure 1. Different methods for nanomaterial synthesis.

Each method of synthesis of nanoparticles has its own merits and demerits along with their unique way of production. Nanomaterials produced by any technique are gaining far-reaching attention in food industry and find exclusive applications that facilitate food storability, nutrition enrichment, as well as assured delivery of bioactive and functional components which are discussed in subsequent section.

Applications of Nanomaterials in Food Sector

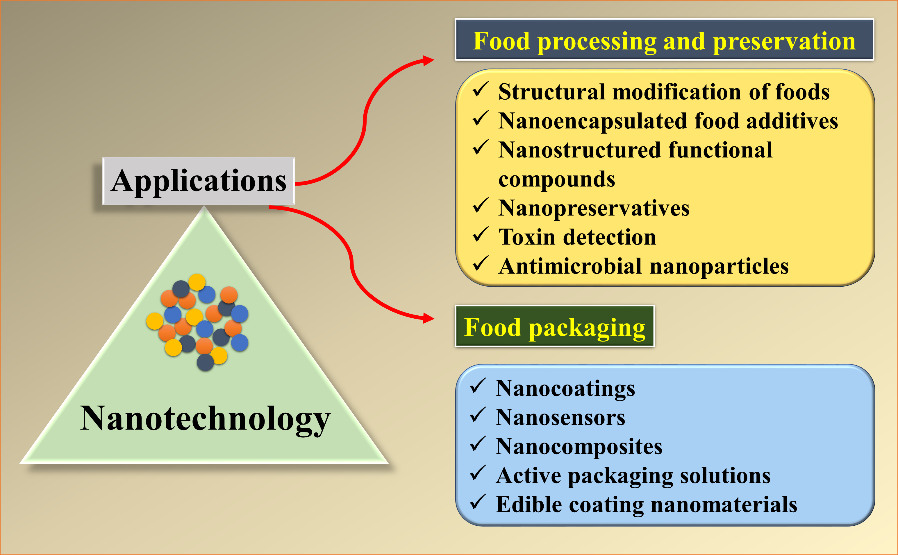

The nanotechnology-based food applications are illustrated in Figure 2. The broad areas include food processing and preservation and food packaging.

Figure 2. Broad application areas of nanotechnology in food sector.

Food processing and preservation

Nanoparticles are being applied for the structural modification of foods, e.g., nano-structured lipids have been introduced to duplicate the creamy texture of the foods in place of fat rich products. Such lipids are used as ingredients in frozen desserts, ice cream, nanostructured mayonnaise dairy spreads, etc. Nano-encapsulation is another prospective that provides possibilities for successive release of multiple bioactive compounds. Additives, like, synthetic lycopene, benzoic acid, ascorbic acid, citric acid, isoflavones, fat soluble vitamins, omega-3 and omega-6 fatty acids, lutein, ß-carotene and enzymes [13] are used in nano-encapsulated forms and find wide-ranging applications in functional food. The nanostructured functional compounds are being encapsulated in protein-based carriers (micelles) or oil-based carriers (liposomes). The nano-carriers can help in preventing thermal degradation and masking unusual flavors and odor of any peculiar additive [14].

Inorganic nanomaterials of various transition metals and their oxides (e.g. iron, silver, titanium dioxide and others), nonmetals (e.g. selenium, silicates, etc.), and alkaline earth metals (e.g. magnesium, calcium, etc.) find direct applications in health food products [15]. Nano selenium is being advertised as a tea additive with greater redox equilibrium and antioxidant activity [16]. SiO2 (E551), MgO (E530), and TiO2 (E171) are permitted by the U.S. Food and Drug Administration (FDA) as anti-caking agent, flavor carriers and coloring additives. Gums, candies, cake icings, puddings pies, and white sauces are incorporated with TiO2 (E171) as a coloring material [17]. Major uses of silver nanoparticles are as a source of micronutrient and an antimicrobial agent (Woodrow Wilson International Centre for Scholars, 2008). Its application is therefore gaining importance in health-foods and antimicrobial packaging. Antibacterial nanosilver particles have been shown to be effective against a wide range of Gram-positive and Gramnegative bacteria, including antibiotic-resistant species. Ashwood et al., found aluminosilicate nanoparticles suited as anti-caking additives [18].

Food packaging

Nanotechnology applications in the area of food packaging hold new potential for increasing its functionality and efficacy. Antioxidants and antimicrobial nanomaterials are getting incorporated in the packaging material as an active packaging approach aiding preservation of food products. Nano materials are used for the wrapping of food products offering solutions by heat resistant properties and modifying the penetration activities of foils, increasing the mechanical, chemical and microbial obstacle effects [19]. Bentonite and montmorillonite have been certified as “generally recognized as safe” by the USFDA and are classified in the Effective Food Contact Substances (FCS) list [20]. Nanoclay particles were embedded in plastic polymers for improved gas-barrier qualities, silver and zinc oxide nanoparticles for antibacterial activities, and titanium dioxide and nitrides nanoparticles for mechanical strength and UV protection, respectively [21].

The use of active nanopackaging aiming efficient nutrient release into food and edible coating materials to minimize the spoilage and extend shelf life has been verified in multiple studies. Metal nanoparticles are being applied in edible coating materials for its improved barrier properties, antimicrobial capacities and controlled release of nutrients. Nanosilver coated fruits and vegetables stay active during transit and storage because of the changed respiration mechanism. Nylon nanocomposite can be utilized to increase oxygen and CO2 barrier characteristics while also removing odors from food [14]. Flores-Lopez et al. [22] found that using thinner hybrid edible films (less than 100 μ thick) enhanced CO2, oxygen and moisture barrier capabilities while also improving shelf life and sensory attributes of food items. Graveland-Bikkera et al., [23] studied the measured release of functional ingredients from the nanocomposites in the packaging material and monitored the migration of minerals, micronutrients and probiotics in food. Kumar and Munstedt [24] discovered that nanosilver particles had antibacterial capabilities against yeast, molds, protozoa, and some viruses. The antibacterial capabilities of metal nanoparticles were attributed to shape, size, exposed surface area, particle internalization, and chemical functions [25]. Moussa et al., [26] evaluated the antifungal influence on strawberries coated with nanosilver impregnated chitosan. After 7 days of storage at ambient condition (25 °C), the fungal deterioration of coated samples was around 10% contrast to 90% of uncoated ones. Costa et al., [27] determined the effect of alginate coating impregnated with silver-montmorillonite nanoparticles on the shelf life of carrots subsequently packed in polypropylene (PP) bags. They found that the combination of active coating and PP bags extended the shelf-life of freshcut carrots to around 70 days compared to 4 days in case of the uncoated samples.

Detection of heavy metals, toxicants, pathogens, contaminants, allergens, non-nutritional parameters and microclimatic factors (humidity, light, temperature etc.) are some of the applications of nanosensors [28]. Nanosensors have great ability to expedite the rate of identification, detection, and quantification of pathogens, decaying substances, and allergy-causing proteins having least detection limits and portability along with improved sensitivity [29]. Goldschmidt [30] discovered that using fluorophores and quantum dots lowered the apparatus size while increasing detection sensitivity. As a result, these nanodevices might have a huge influence on food security. Toxin detection has been investigated using nanoparticle-based molecular mimicry and colorimetric assays, with positive findings for cholera toxin detection [31]. A single bacterium could be isolated in less than 20 min utilizing fluorescent-based quantification of bacteria by using antibody doped nanoparticles of silica [32]. Thus, this analytical methodology was able to decrease the typical plating procedure of 16-18 h to only a few min, and it was even able to identify the existence of even some individual cellular impurities, which is impossible to achieve with traditional methods. Nanosensors are often used on food packaging to monitor external and interior product conditions as well as to precisely identify various pollutants in food [33]. Nanosensors are also gaining traction as a powerful tool for monitoring the interactions between food and packaging materials in storage. As a consequence of any interaction, the nanosensor provides a response (visual and electric signal) correlating with the status of the food product. Nanobarcodes have already been commercially accepted for food authenticity [13].

Potential Health Risks, Safety Concerns, Toxicity Issues and Other Associated Challenges

The challenging task is to produce safe edible delivery systems using cost-effective processing operations [34]. Consumption of foods contacted with nanopackages may constitute an exposure pathway and pose a considerable health risk due to subsequent migration or leaching of particulate nanomaterials into the food from the packaging. Such effect certainly depends on nature/type of packaging matrix, toxicity of the used nanomaterial, degree of migration and uptake rate of the particular food [35]. Higher amounts of such compounds inhaled or absorbed through the skin pose a major threat to human health, particularly in terms of long-term toxicity [36]. These nanoparticles could build up in different organs like stomach, small intestine, kidneys, liver and spleen [37]. Problems like kidney damage, lung damage and hepatic injury could occur due to single oral intake of ZnO nanoparticles [38]. The application of titanium oxide and its downstream disposal can have adverse effect on human health as well as environment [39].

The materials behave very differently at the nanoscale level and we still have partial technical knowledge of its analysis. A comprehensive understanding of nano-range functionalities and harmfulness of nanomaterials will further improve their practical applications and safety requirements. Synthesis of nanoparticles by different chemical methods has negative outcomes and produces harmful non-ecofriendly by-products resulting in severe environmental pollution [40]. In addition to public awareness, risk assessment programmes, regulatory policies and biosafety concerns must be taken care of while processing of nanotechnology-based food products, its packaging and subsequent consumption [41,42]. Furthermore, prior to commercial application of nanoparticles, in vitro and in vivo research concerning the nanoparticle interactions with living matters are required [43].

Conclusions and Future Aspects

Nanotechnology is being visualized as a quickly evolving field with prospective to revolutionize food systems. There have been tremendous progresses in the nanotechnology applications in food science and research. From enhancing product shelf life to advanced isolation of microbes to better-quality food storage and safety to tracing-tracking of contaminants/pollutants to detection of toxins/pathogens to nutritional or functional supplements through food, nanotechnology has touched almost every spectrum of food processing sector. The direct applications mostly include mixing of coloring agents, fragrances, nano-preservatives, antioxidants, and bioactive compounds like polyphenols, vitamins, fatty acids, etc. Indirect applications encompass the usage of nanosized substances in packaging material, nanosensors, and usage of catalysts in hydrogenation in case of fats. Recent advancements in the field of nanoscience-based applications have shown prospects to re-frame processing line, re-structure the production chain, promote natural resource conservation, and even re-define the food habits. Such advancements have major implications for the agri-food systems and will ultimately have vital impacts on the quality, safety, storability, and security of foods benefiting both producers and consumers influencing the economic outlook. However, more research is needed based on precautionary principles, particularly in regards to NSM migration patterns in food matrix, human cytotoxicity of nanoparticles, and their potential effects on consumer health and safety, as well as the environment. Potential risks, toxicological issues, and environmental considerations must all be addressed. The concerned rules and regulations are only to be laid to overcome various prevailing safety challenges after which, it would rule the entire food industrial domain.

References

2. Avella M, De Vlieger JJ, Errico ME, Fischer S, Vacca P, Volpe MG. Biodegradable starch/clay nanocomposite films for food packaging applications. Food Chemistry. 2005 Dec 1;93(3):467-74.

3. Bajpai SK, Chand N, Chaurasia V. Nano zinc oxide-loaded calcium alginate films with potential antibacterial properties. Food and Bioprocess Technology. 2012 Jul;5(5):1871-81.

4. Bott J, Störmer A, Franz R. A comprehensive study into the migration potential of nano silver particles from food contact polyolefins. InChemistry of food, food supplements, and food contact materials: from production to plate 2014 (pp. 51-70). American Chemical Society.

5. Prakash A, Sen S, Dixit R. The emerging usage and applications of nanotechnology in food processing industries: The new age of nanofood. Int. Journal of Pharmaceutical Sciences. Rev. Res. 2013;22(1):107-11.

6. Aher N, Banerjee S, Bhansali S, Yadav R, Shidore M, Mhaske S, et al. Poly (ethylene glycol) versus dendrimer prodrug conjugates: Influence of prodrug architecture in cellular uptake and transferrin mediated targeting. Journal of Biomedical Nanotechnology. 2013 May 1;9(5):776-89.

7. Kulkarni SK. Synthesis of nanomaterials—I (Physical methods). InNanotechnology: principles and practices 2015 (pp. 55-76). Springer, Cham.

8. Kulkarni SK. Synthesis of nanomaterials—II (Chemical methods). InNanotechnology: principles and practices 2015 (pp. 77-109). Springer, Cham.

9. Bansal V, Bharde A, Ramanathan R, Bhargava SK. Inorganic materials using ‘unusual’microorganisms. Advances In Colloid and Interface Science. 2012 Nov 1;179:150-68.

10. Kulkarni SK. Synthesis of nanomaterials—III (Biological methods). InNanotechnology: Principles and Practices 2015 (pp. 111-123). Springer, Cham.

11. Sankar R, Karthik A, Prabu A, Karthik S, Shivashangari KS, Ravikumar V. Origanum vulgare mediated biosynthesis of silver nanoparticles for its antibacterial and anticancer activity. Colloids and Surfaces B: Biointerfaces. 2013 Aug 1;108:80-4.

12. Reddy NJ, Vali DN, Rani M, Rani SS. Evaluation of antioxidant, antibacterial and cytotoxic effects of green synthesized silver nanoparticles by Piper longum fruit. Materials Science and Engineering: C. 2014 Jan 1;34:115-22.

13. Chaudhry, Q., Castle, L., & Watkins, R. (Eds.). (2010). Nanotechnologies in food. Royal Society of Chemistry Publishers, ISBN 978- 0-85404-169-5.

14. Sahoo M, Vishwakarma S, Panigrahi C, Kumar J. Nanotechnology: Current applications and future scope in food. Food Frontiers. 2021 Mar;2(1):3-22.

15. Chaudhry Q, Scotter M, Blackburn J, Ross B, Boxall A, Castle L, Aitken R, et al. Applications and implications of nanotechnologies for the food sector. Food Additives and Contaminants. 2008 Mar 1;25(3):241-58.

16. Zhang W, Zhang J, Ding D, Zhang L, Muehlmann LA, Deng SE, at al. Synthesis and antioxidant properties of Lycium barbarum polysaccharides capped selenium nanoparticles using tea extract. Artificial Cells, Nanomedicine, and Biotechnology. 2018 Oct 3;46(7):1463-70.

17. Weir A, Westerhoff P, Fabricius L, Hristovski K, Von Goetz N. Titanium dioxide nanoparticles in food and personal care products. Environmental Science & Technology. 2012 Feb 21;46(4):2242-50.

18. Ashwood P, Thompson RP, Powell JJ. Fine particles that adsorb lipopolysaccharide via bridging calcium cations may mimic bacterial pathogenicity towards cells. Experimental Biology and Medicine. 2007 Jan;232(1):107-17.

19. Rhim JW, Park HM, Ha CS. Bio-nanocomposites for food packaging applications. Progress in Polymer Science. 2013 Oct 1;38(10-11):1629-52.

20. Störmer A, Bott J, Kemmer D, Franz R. Critical review of the migration potential of nanoparticles in food contact plastics. Trends in Food Science & Technology. 2017 May 1;63:39-50.

21. Chaudhary P, Fatima F, Kumar A. Relevance of nanomaterials in food packaging and its advanced future prospects. Journal of Inorganic and Organometallic Polymers and Materials. 2020 Dec;30(12):5180-92.

22. Flores-López ML, Cerqueira MA, de Rodríguez DJ, Vicente AA. Perspectives on utilization of edible coatings and nanolaminate coatings for extension of postharvest storage of fruits and vegetables. Food Engineering Reviews. 2016 Sep;8(3):292-305.

23. Graveland-Bikker JF, De Kruif CG. Unique milk protein based nanotubes: food and nanotechnology meet. Trends in Food Science & Technology. 2006 May 1;17(5):196-203.

24. Kumar R, Münstedt H. Silver ion release from antimicrobial polyamide/silver composites. Biomaterials. 2005 May 1;26(14):2081-8.

25. Diaz-Visurraga J, Cardenas G, García A. Morphological changes induced in bacteria as evaluated by electron microscopy. Microsc. Sci. Technol. Appl. Educ. 2010:307-15.

26. Moussa SH, Tayel AA, Alsohim AS, Abdallah RR. Botryticidal activity of nanosized silver‐chitosan composite and its application for the control of gray mold in strawberry. Journal of Food Science. 2013 Oct;78(10):M1589-94.

27. Costa C, Conte A, Buonocore GG, Lavorgna M, Del Nobile MA. Calcium-alginate coating loaded with silver-montmorillonite nanoparticles to prolong the shelf-life of fresh-cut carrots. Food Research International. 2012 Aug 1;48(1):164-9.

28. Scott, N., and Chen, H. (2003). Nanoscale science and engineering of agriculture and food systems. Report submitted to Cooperative State research, Education and Extension Service (CSREES), U.S. Dept. of Agriculture. Website: http://www.nseafs. cornell.edu

29. Silvestre C, Duraccio D, Cimmino S. Food packaging based on polymer nanomaterials. Progress in Polymer Science. 2011 Dec 1;36(12):1766-82.

30. Goldschmidt MC. The use of biosensor and microarray techniques in the rapid detection and identification of salmonellae. Journal of AOAC International. 2006 Mar 1;89(2):530-7.

31. Tark SH, Das A, Sligar S, Dravid VP. Nanomechanical detection of cholera toxin using microcantilevers functionalized with ganglioside nanodiscs. Nanotechnology. 2010 Oct 4;21(43):435502.

32. Stanković M, Gabrovska M, Krstić J, Tzvetkov P, Shopska M, Tsacheva T, et al. Effect of silver modification on structure and catalytic performance of Ni-Mg/diatomite catalysts for edible oil hydrogenation. Journal of Molecular Catalysis A: Chemical. 2009 Jan 5;297(1):54-62.

33. Li Z, Sheng C. Nanosensors for food safety. Journal of Nanoscience and Nanotechnology. 2014 Jan 1;14(1):905-12.

34. Dupas C, Lahmani M, editors. Nanoscience: Nanotechnologies and nanophysics. Springer Science & Business Media; 2007 Feb 13.

35. Cushen M, Kerry J, Morris M, Cruz-Romero M, Cummins E. Nanotechnologies in the food industry–Recent developments, risks and regulation. Trends In Food Science & Technology. 2012 Mar 1;24(1):30-46.

36. He X, Hwang HM. Nanotechnology in food science: Functionality, applicability, and safety assessment. Journal of Food and Drug Analysis. 2016 Oct 1;24(4):671-81.

37. McClements DJ, Xiao H. Is nano safe in foods? Establishing the factors impacting the gastrointestinal fate and toxicity of organic and inorganic food-grade nanoparticles. npj Science of Food. 2017 Nov 20;1(1):1-3.

38. Esmaeillou M, Moharamnejad M, Hsankhani R, Tehrani AA, Maadi H. Toxicity of ZnO nanoparticles in healthy adult mice. Environmental Toxicology and Pharmacology. 2013 Jan 1;35(1):67-71.

39. Yang Y, Doudrick K, Bi X, Hristovski K, Herckes P, Westerhoff P, Kaegi R. Characterization of food-grade titanium dioxide:Technology. 2014 Jun 3;48(11):6391-400. the presence of nanosized particles. Environmental Science &

40. Singhal G, Bhavesh R, Kasariya K, Sharma AR, Singh RP. Biosynthesis of silver nanoparticles using Ocimum sanctum (Tulsi) leaf extract and screening its antimicrobial activity. Journal of Nanoparticle Research. 2011 Jul;13(7):2981-8.

41. Bajpai VK, Kamle M, Shukla S, Mahato DK, Chandra P, Hwang SK, et al. Prospects of using nanotechnology for food preservation, safety, and security. Journal of Food and Drug Analysis. 2018 Oct 1;26(4):1201-14.

42. Yu Y, Zhang S, Ren Y, Li H, Zhang X, Di J. Jujube preservation using chitosan film with nano-silicon dioxide. Journal of Food Engineering. 2012 Dec 1;113(3):408-14.

43. Das S, Jagan L, Isiah R, Rajesh B, Backianathan S, Subhashini J. Nanotechnology in oncology: Characterization and in vitro release kinetics of cisplatin-loaded albumin nanoparticles: Implications in anticancer drug delivery. Indian Journal of Pharmacology. 2011 Jul;43(4):409.