Introduction

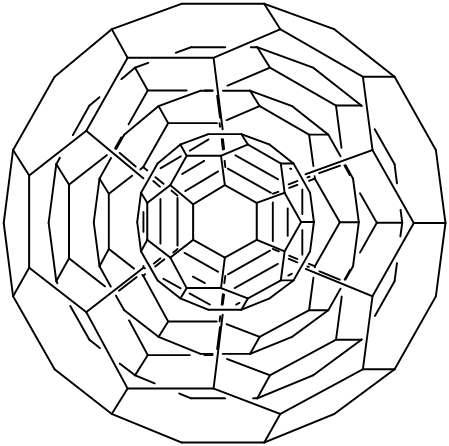

The incorporation of carbon Nano-onions (CNOs) into polymeric materials represents a significant stride in materials engineering, leveraging their unique spherical, multi-layered structures to boost the mechanical, thermal, and conductive properties of polymers. Figure 1 shows the chemical structure of CNOs. Functionalized CNOs can be tailored through chemical modifications to enhance their compatibility with various polymer matrices, a practice that has seen increasing utilization across diverse fields. This editorial article examines the role of these functionalized nanoparticles in revolutionizing polymer composites, specifying briefly the techniques for their functionalization, the general types of polymer matrices used, their effects on composite properties, and their broadening range of applications.

Figure 1. Chemical structure of CNOs.

Functionalization of CNOs

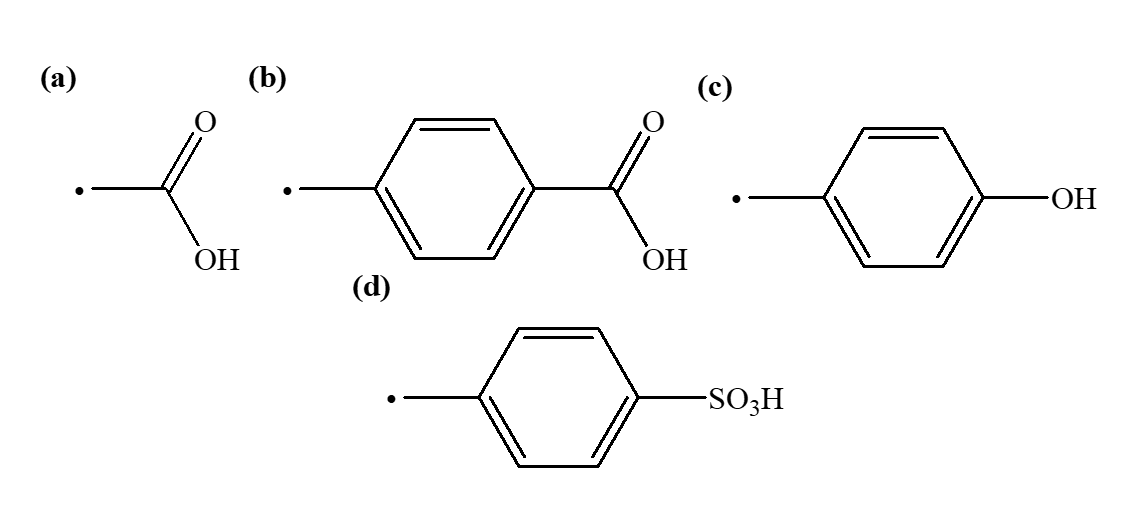

Functionalizing CNOs involves attaching specific functional groups such as carboxyl, benzoyl, hydroxyaryl, or sulfophenyl, which are instrumental in enhancing their dispersibility and interfacial bonding within polymer matrices [1]. Figure 2 displays the functional groups: carboxyl, benzoyl, hydroxyaryl, and sulfophenyl. Techniques such as chemical oxidation, which introduces carboxyl groups [2]; benzoylation, which adds benzoyl groups [3]; hydroxyarylation, which adds hydroxyaryl groups [4]; and phenylation followed by sulfonation, which adds sulfophenyl groups [5] are commonly employed to increase the utility of CNOs in polymer composites [6]. These modifications facilitate stronger interactions between the CNOs and the polymer chains, resulting in composites that exhibit superior mechanical and thermal properties.

Figure 2. Functional groups: (a) carboxyl, (b) benzoyl, (c) hydroxyaryl, and (d) sulfophenyl.

Polymer Matrices of CNO-filled Composites

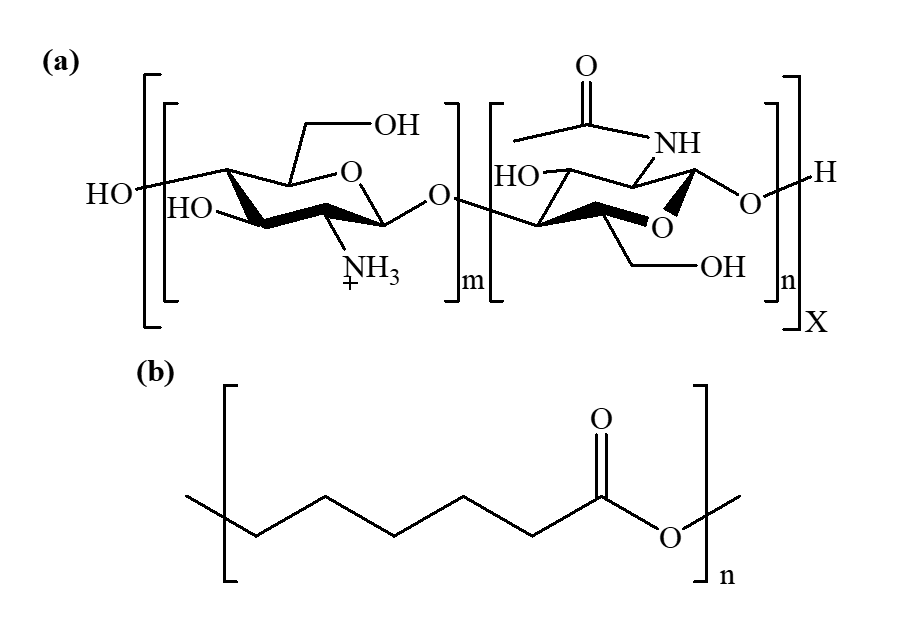

Selecting the appropriate polymer matrices is crucial for optimizing the performance of CNO-filled composites. Common matrices include chitosan [2,3,7] and poly(ε-caprolactone) (PCL) [8,9]. Figure 3 displays the chemical structures of chitosan and PCL. Biopolymers such as chitosan exhibit good solubility in conventional organic solvents compared to chitin [10]. PCL is renowned for its biocompatibility and biodegradability, underlining its importance in specialized medical applications [11]. Incorporating CNOs into these polymers often results in significant property enhancements. By modifying the characteristics of CNOs, their interactions with these polymers can be finely tuned to create materials that are not only structurally robust but also functionally adaptable to complex environments.

Figure 3. Chemical structures of (a) chitosan and (b) PCL.

Effects of Functionalized CNOs on Composite Properties

Functionalized CNOs (f-CNOs) primarily contribute to the mechanical strengthening of polymer composites through effective stress transfer mechanisms at the nano-level [12]. These enhancements are further supported by improvements in thermal stability [5] and electrical conductivity [9], which are essential for maintaining operations under varying working conditions. Additionally, the presence of functional groups on the CNOs enhances the interactions between these f-CNOs and the polymer chains, leading to increased dispersion of f-CNOs within the polymer matrix [1,9]. This uniform distribution helps prevent the aggregation of nanoparticles, thus enhancing the properties and improving the composite’s overall performance and durability over extended periods.

Applications of f-CNOs-filled Composites

The strategic incorporation of f-CNOs into polymer matrices unlocks numerous applications across various industries. In the field of biomedicine, these composites are used to develop innovative regenerative tissue scaffolds [2,7], drug delivery systems [8,12], and biomaterials [9], capitalizing on the biocompatibility and enhanced mechanical properties provided by f-CNOs. Energy storage is another critical area, with f-CNOs-filled composites being explored for developing next-generation batteries and supercapacitors [3,4], which offer higher efficiency and extended life cycles. In additional applications, these composites are employed to produce electrode materials for electrochemical sensors, proton exchange membranes for fuel cells [5], and polymer nanocomposites for thermal management [1].

Conclusions

The functionalization of CNOs and their incorporation into polymeric materials represent a dynamic and rapidly evolving field in materials science, promising to meet the demands for materials that combine high performance with functional versatility. As research continues to advance, new methods of CNO functionalization and improved techniques for composite processing are expected to emerge, further broadening the applications of these materials. The ongoing development and optimization of CNO-filled composites not only pave the way for innovative applications in medicine and technology but also hold the potential for significant environmental and economic impacts by offering sustainable alternatives to conventional materials.

References

2. Castro JI, Chaur MN, Llano CH, Valencia Zapata ME, Mina Hernandez JH, Grande-Tovar CD. Biocompatibility study of electrospun nanocomposite membranes based on chitosan/polyvinyl alcohol/oxidized carbon nano-onions. Molecules. 2021 Aug 6;26(16):4753.

3. Fernández DA, Velásquez JD, Plonska-Brzezinska ME, Chaur MN. Evaluation of chitosan composites with functionalized carbon nano-onions for supercapacitor applications. Electrochimica Acta. 2024 Nov 10;504:144886.

4. Siemiaszko G, Breczko J, Hryniewicka A, Ilnicka A, Markiewicz KH, Terzyk AP, et al. Composites containing resins and carbon nano-onions as efficient porous carbon materials for supercapacitors. Scientific Reports. 2023 Apr 24;13(1):6606.

5. Liu L, Lu Y, Pu Y, Li N, Hu Z, Chen S. Highly sulfonated carbon nano-onions as an excellent nanofiller for the fabrication of composite proton exchange membranes with enhanced water retention and durability. Journal of Membrane Science. 2021 Dec 15;640:119823.

6. Olejnik P, Gniadek M, Echegoyen L, Plonska‐Brzezinska ME. A nanocomposite containing carbon nano‐onions and polyaniline nanotubes as a novel electrode material for electrochemical sensing of daidzein. Electroanalysis. 2021 Apr;33(4):1107-14.

7. Grande Tovar CD, Castro JI, Valencia CH, Navia Porras DP, Herminsul Mina Hernandez J, Valencia Zapata ME, et al. Nanocomposite films of chitosan-grafted carbon nano-onions for biomedical applications. Molecules. 2020 Mar 7;25(5):1203.

8. Mamidi N, Zuníga AE, Villela-Castrejón J. Engineering and evaluation of forcespun functionalized carbon nano-onions reinforced poly (ε-caprolactone) composite nanofibers for pH-responsive drug release. Materials Science and Engineering: C. 2020 Jul 1;112:110928.

9. Mamidi N, Gamero MR, Delgadillo RM, Castrejón JV, Zúníga AE. Engineering of functionalized carbon nano-onions reinforced nanocomposites: Fabrication, biocompatibility, and mechanical properties. Journal of Materials Research. 2020 Apr;35(8):922-30.

10. Shamsuri AA, Abdan K, Md Jamil SN. Preparations and properties of ionic liquid-assisted electrospun biodegradable polymer fibers. Polymers. 2022 Jun 7;14(12):2308.

11. Shamsuri AA, Md Jamil SN, Yusoff MZ, Abdan K. Methods and Mechanical Properties of Polymer Hybrid Composites and Hybrid Polymer Composites: Influence of Ionic Liquid Addition. Applied Mechanics. 2024 Mar 1;5(1):1-19.

12. Mamidi N, Velasco Delgadillo RM, Gonzáles Ortiz A, Barrera EV. Carbon nano-onions reinforced multilayered thin film system for stimuli-responsive drug release. Pharmaceutics. 2020 Dec 13;12(12):1208.